The WIMA Quality

WIMA can claim a quality leadership in the film capacitor industry which is proven regularly by top customer evaluations and quality/service awards.

All WIMA factories are approved to DIN EN ISO 9001:2015. This certifies that organisation, equipment and monitoring of quality assurance in our factories correspond to internationally recognized standards. All WIMA products are manufactured in accordance with IEC specifications.

For the sake of environment we give priority to the use of recyclable substances and the reduction of packing materials. In all our factories we have implemented a sophisticated energy and water recycling system for efficient use and spare of precious resources.

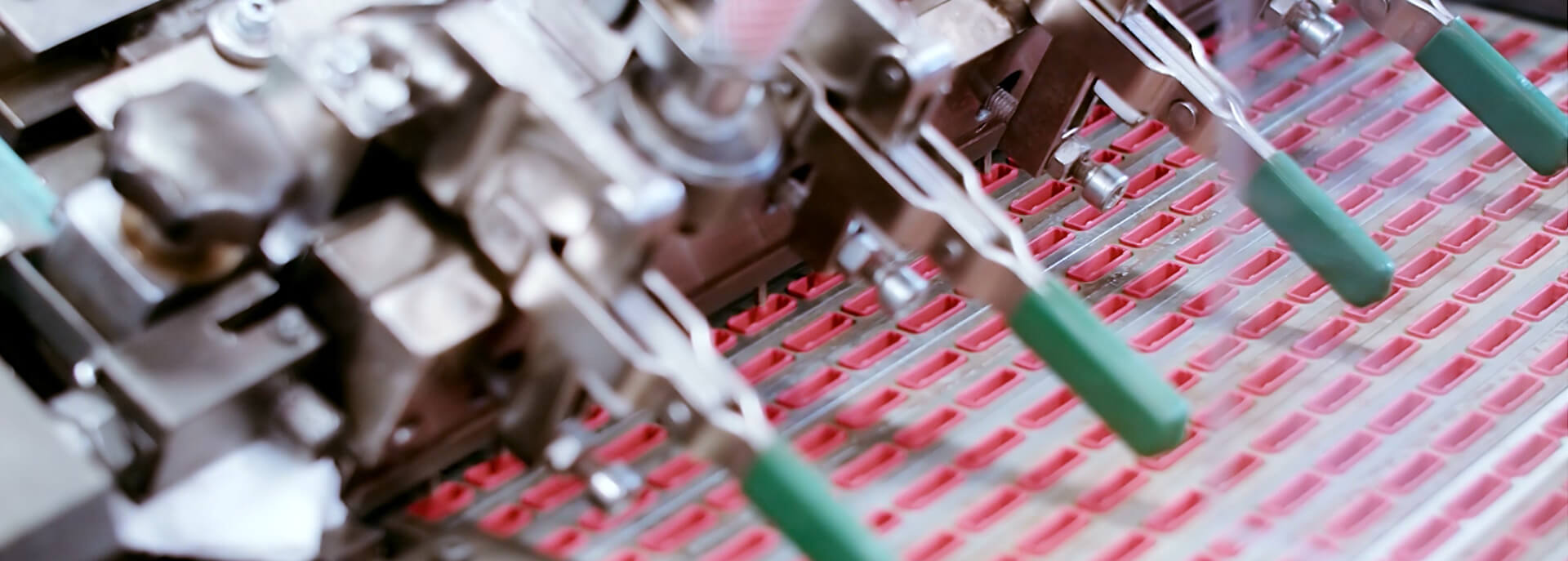

WIMA Process Control System

All WIMA plants are subject to WPCS (WIMA Process Control System) to optimize quality. WPCS is a quality surveillance and optimization system developed by WIMA. It is a major part of our quality-oriented production.

Points of application of WPCS during production process:

- Incoming material inspection

- Metallization

- Film inspection

- Schoopage

- Pre-healing

- Pin attachment

- Cast resin preparation/ Encapsulation

- 100 % final inspection

- Testing as per customer requirements

According to RoHS-regulation of the EU all electronic components have to be lead-free. WIMA is fully compliant with this rule by offering 100% of its products without processing lead.

WPCS |

System 1 |

System 2 |

|

|

|

Consistent Quality Status |