Dielectric

Characteristics of the plastic film dielectrics

Characteristics of Metallized Film Capacitors in Comparison with Other Dielectrics

| PET | PP | PPS | NPO | X7R | Tantal | |

| Dielectric constant 1 kHz/23°C |

3.3 (positive as temperature rise) | 2.2 (negative as temperature rise) | 3.0 (very constant versus temperature) | 12...40 | 700...2000 | 26 |

| Operating temperature (°C) | -55...+105 (+125) | -55...+105 | -55...+140 | -55...+125 | -55...+125 | -55...+125 |

| Dielectric absorption (%) | 0.2...0,25 | 0.05...0,10 | 0.05 | 0.6 | 2.5 | n.a. |

| ΔC/C versus temperature (%) | ± 5 | ± 2.5 | ± 1.5 | ± 0.3 | ± 15 | ± 10 |

| ΔC/C versus voltage (%) | negligible | negligible | negligible | negligible | -20 | negligible |

| ΔC aging rate (%/h decreasing) | negligible | negligible | negligible | negligible | 2 | n.a. |

| Dissipation factor (%) 1 kHz 10 kHz 100 kHz |

0.8 1.5 3.0 |

0.05 0.08 0.25 |

0.2 0.25 0.5 |

0.10 0.10 0.10 |

2.5 - - |

8 - - |

| ESR | low | very low | very low | low | moderate | high |

| Ris (MΩ x µF) 25 °C 85 °C |

10000 1000 |

100000 10000 |

10000 1000 |

10000 1000 |

1000 500 |

100 10 |

| Capacitance range from pF to µF | 1000...680 | 27...400 | 10000...2.2 | 1...0.1 | 100...2.2 | 100000...1000 |

| Capacitance tolerance (+/- %) | 5/10/20 | 1/2.5/5/10 | 2.5/5/10/20 | 5/10 | 10/20 | 10/20 |

| Self-healing | yes | yes | yes | no | no | no |

| Typical failure mode at end of life | open | open | open | short | short | short |

| Reliability | high | high | high | high | moderate | low |

| Piezoelectric effect | no | no | no | no | yes | yes |

| Resistance to thermal and mechanical shock | low | low | low | moderate to high | moderate to high | low |

| Polarity | no | no | no | no | no | yes |

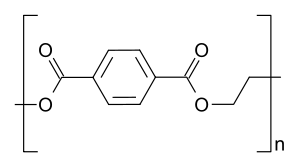

Polyester (Polyethylene-terephthalate)

Basic molecule

Typical graphs

Capacitance change versus temperature

Capacitance change versus temperature

(f = 1 kHz) ( general guide)

Insulation resistance change versus temperature

Insulation resistance change versus temperature

(general guide)

Dissipation factor change versus frequency

Dissipation factor change versus frequency

(general guide)

Max. working temperature: +125°C

Film thickness: > 0.7 µm

Production process: extruded, biaxially stretched

Manufacturing Process of Polyester Film

Extrusion

Bi-axial streching

Crystallisation

tangled, felted

tangled, felted streched

streched crystallised (cross-linked, knotted)

crystallised (cross-linked, knotted)

Fields of Applications for Polyester Capacitors

- Decoupling

- Coupling

- Blocking

Properties

- Advantageous price/performance ratio

- Advantageous capacitance/volume ratio

- Substitution of low quality electrolytic and tantal capacitors

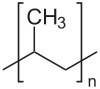

Polypropylene

Basic molecule

Typical graphs

Capacitance change versus temperature

Capacitance change versus temperature

(f = 1 kHz) (general guide)

Insulation resistange change versus temperature

Insulation resistange change versus temperature

(general guide)

Disipation factor change versus frequency

Disipation factor change versus frequency

(general guide)

Max. working temperature: +105°C

Film thickness: > 4 µm

Production process: extruded, biaxially stretched

Manufacturing process of Polypropylene film

Extrusion

Bi-axial streching

Crystallisation

tangled, felted

tangled, felted streched

streched crystallised (cross-linked, knotted)

crystallised (cross-linked, knotted)

Fields of Applications for Polypropylene Capacitors

- Sample and hold

- Oscillator circuits

- Resonating circuits

- Deflection systems

- Power supplies

- Converters

- Lighting

- Audio applications

Properties

- Lowest dissipation factor

- Constantly negative TKc

- Close tolerances up to 1%